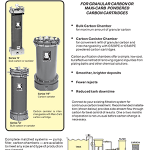

SERFILCO pioneered the use of activated granular carbon canisters in a chamber positioned downstream of the primary filter system to purify filtered solution. Because adsorption of organics through the carbon is most effective at low flow rates in order to maximise efficiency we suggest that a ‘bypass’ is fitted between the primary filter and downstream carbon chamber. This permits a controlled volume of clean solution to be diverted through the column of the carbon as required, or as many customers do, on a continuous low flow. This type of system gives two different ways of carbon treating

For continuous carbon treatment. Simply open the bypass valve between chambers a small amount and allow a percentage of the pump flow to continuously pass through the carbon chamber and back to process tank (the remainder of the flow will continue to pass through the filter chamber and back to process tank).

For batch carbon treatment the valve between the filter chamber and carbon chamber is closed during normal operation, when organic contamination reaches increased levels the bypass valve is fully opened and 100% of the flow passes through the carbon until the organics are removed

This innovative SERFILCO design eliminates down-time, labour intensive powdered carbon treatments, inefficient carbon discs and cartridges and lost chemistry due to constant manual change outs and carbon treatment.